.

Retrievable Inflatable Packers & Plugs

پکر منبسط شونده

اینفلیتبل پکر

✅ API 11D1 Qualified

✅ Suitable for Coiled Tubing & Drill Pipe

✅ Applicable in Vertical, Deviated & Horizontal Wells

Product Overview

Modern well intervention and stimulation operations require flexible, reliable, and cost-effective isolation solutions—especially in mature and producing wells. Conventional mechanical packers often require tubing retrieval or complex workover operations, increasing non-productive time and operational risk.

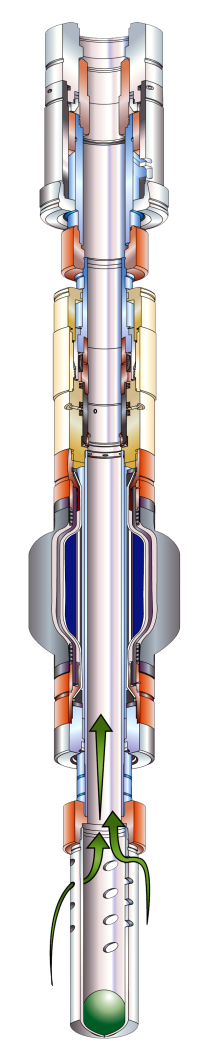

The PETROCO Retrievable Inflatable Packer eliminates these challenges by providing a fully retrievable, inflatable sealing solution that can be deployed through existing production tubing. Once positioned at the target depth, the inflatable element expands to form a high-integrity seal against casing or open-hole walls, enabling safe and efficient zonal isolation.

After completing the operation, the packer is deflated and retrieved without damaging the wellbore or completion equipment.

1. Run‑in‑hole through production tubing using coiled tubing or drill pipe

2. Positioning at the target depth

3. Inflation of the elastomer element using designated fluid

4. Effective zonal isolation during the operation

5. Pressure equalization, deflation, and safe retrieval

How It Works

Key Features & Benefits

. Eliminates the need to pull production tubing, reducing NPT and operational cost

. Compatible with both coiled tubing and drill pipe

. Reliable sealing performance in open-hole and cased-hole environments

. Suitable for high-pressure well conditions

. Operable in vertical, deviated, and horizontal wells

. Controlled pressure equalization mechanism ensures safe retrieval

Design Options & Configurations

Depending on application requirements, the Inflatable Packer can be supplied with:

. High-pressure enhanced design

. Long-element configuration for improved sealing

. Sour-service compatible elastomers (H₂S environments)

. Customized dimensions for special well conditions

Typical Applications

. Well intervention and remedial operations

. Stimulation and selective matrix acidizing

. Pressure testing and integrity verification

. Temporary zonal isolation

. Water shut‑off operations

Frequently Asked Questions (FAQ)

Can the packer be used in horizontal wells?

Yes, the tool is designed for vertical, deviated, and horizontal well applications.

Is the packer fully retrievable?

Yes, after pressure equalization and deflation, the packer can be safely retrieved.

What fluids can be used for inflation?

Typical inflation fluids include water or brine. Other fluids can be evaluated upon request.

Is the packer suitable for high-pressure operations?

Yes, the packer is designed for high-pressure applications within specified limits.